Agrippa by Golden Coast Custom, a French bouncer

Created in 2011 by Fabrice Ravenet, Golden Coast Custom offers a whole range of services for the Off-road world, especially chassis and turn-key builds. He own a shop, but offers also a « in your garage » service. In this case, his Land Rover Discovery is his own « mobile shop ».

you want some help to realize a part or a full tubular chassis

you want to add a cage to your ride

you need any custom part

https://www.facebook.com/GoldenCoastCustom

www.goldencoastcustom.com

Fabrice is the specialist in one of a kind things.

He also have a competition background, with engagements as a pilot in the “24 Hours OffRoad” and as a co-pilot in the “24 Hours Morocco”.

Fabrice is a long term offroader. Everything started with a Lada Niva. He has been the president of the Nivaventure off-road club, a famous french Lada club. At this time he started to build Ladas and made a transfer case Low Range reduction gear. You still can find this gear under the name “Fabrice kit”. His passion for the Niva brought him to build a hot-rod version a few years ago, the Nivrod.

Wanting to have more power while trailriding, he bought a Mercedes G with an inline 6. After owning it for one year, he teared it down in parts and rebuilt it entirely. You can already feel his passion for wrenching !

His love for off-roading pushed him to compete in several Trials (short time courses with obligatory obstacles and penalties) and trips like the “Trophée Cévenol”, the “Raid Alpin Italie France”.

In en 2009 he lived what you can call a BIG U-Turn. He decided to transform his Mercedes G in a buggy. For this purpose, his step-father helped him a lot, teaching him his mechanical knowledge. And after one year the famous “Tas de Tubes” (literally “Stack of tubbing”) was born.

After this experience, he decided to quit his job as a metallurgical engineer and focus on his passion, wrenching, building buggies, custom off-road accessories. His motto is : » enjoy, live and enjoy the passion« . His former boss helped him and November the 11th, GoldenCoastCustom was opening.

Fabrice had obviously a project in mind, a big, huge project. That’s what I’m offering you to discover right know.

As he says, he doesn’t have the ambition of being rich, but wants to develop this kind of vehicles in France, while maintaining them affordable. You can enjoy owning one for prices starting at 20 – 25 000€. He is fighting for the opening of new spots and OHV parks, organizing meetings and maybe someday, a competition.

Agrippa or the birth of a French Rock Bouncer

Fan of the US Rock Bouncers – to bounce meaning to rebound, this word characterize machines used to climb steps, cliffs and bounty hills – Fabrice watched, analyzed during hours images and videos of US made buggies. For example, the very famous Tim Cameron’s Showtime or Tanner Family buggies, do a search on Google or Youtube, you’ll find a pile of information. After some time, he had a precise idea of what was working and started the creation of Agrippa.

He started to buy the most important parts in this kind of project : the axles, a rear 14 Bolts and a front Dana 60 fully equipped by RCV (translation : every components come from RCV, a US company specialized in high end Performance Parts for this kind of application). He chose the best you could by on a catalog. You can always find bigger, better parts, but they are custom made and the cost tend to go up exponentially. This setup is made in chromoly parts. This alloy guaranties a much needed bullet proof strength, as you realize putting pedal to the metal in a bounty hill has quite a tendency to shatter drivetrain parts… RCV guarantees its Dana 60 axleshafts up to 47” tires. When they say it’s tough, it’s tough.

Hubs come from SolidAxle Components another US company.

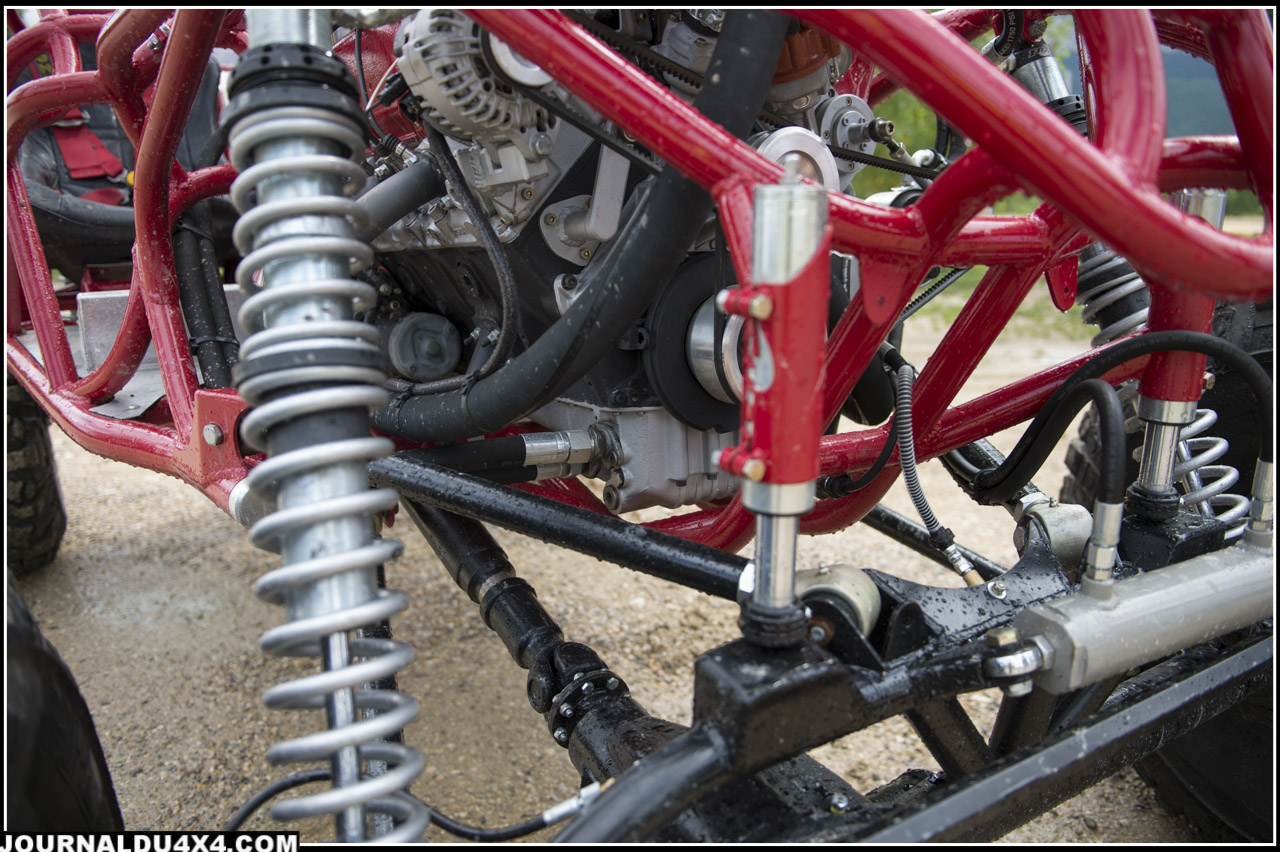

Steering comes from the US as well. It was purchased from PSC motorsports, it’s a full hydraulic system, with SE ram and HD pump. These are rugged, proven parts and regularly used for this kind of buggies.

Cost investment is quite huge as the whole axles, wheels, tires, steering package is about 12 000 € (16000US$).

To work, Fabrice doesn’t use plans. He has « everything in the head« . His way of conception is to start with mocking up the drivetrain, then star to build the subframe and cage. Speaking about the cage, you can notice that he’s a big fan of curved shapes, but also has his own style, trying to create a homogeneous chassis, with a racing look, instead of building a “strength oriented only cage”.

He has to spend more time to achieve his goals, but in the end, the buggy will not leave anyone indifferent. The complexity of the chassis and the personal touch, sensual curves Fabrice adds to all of his builds makes a big impact to the eye. Like it or not, it’s a matter of personal preference, but this chassis is efficient while having a strong aesthetic bias.

Aesthetically my dear Watson

Once the axles set up on a mocking table, tubs start to take shape, and after exactly 126 bends the chassis is done. He used about 100m (328 ft) and spent 3 weeks building it.

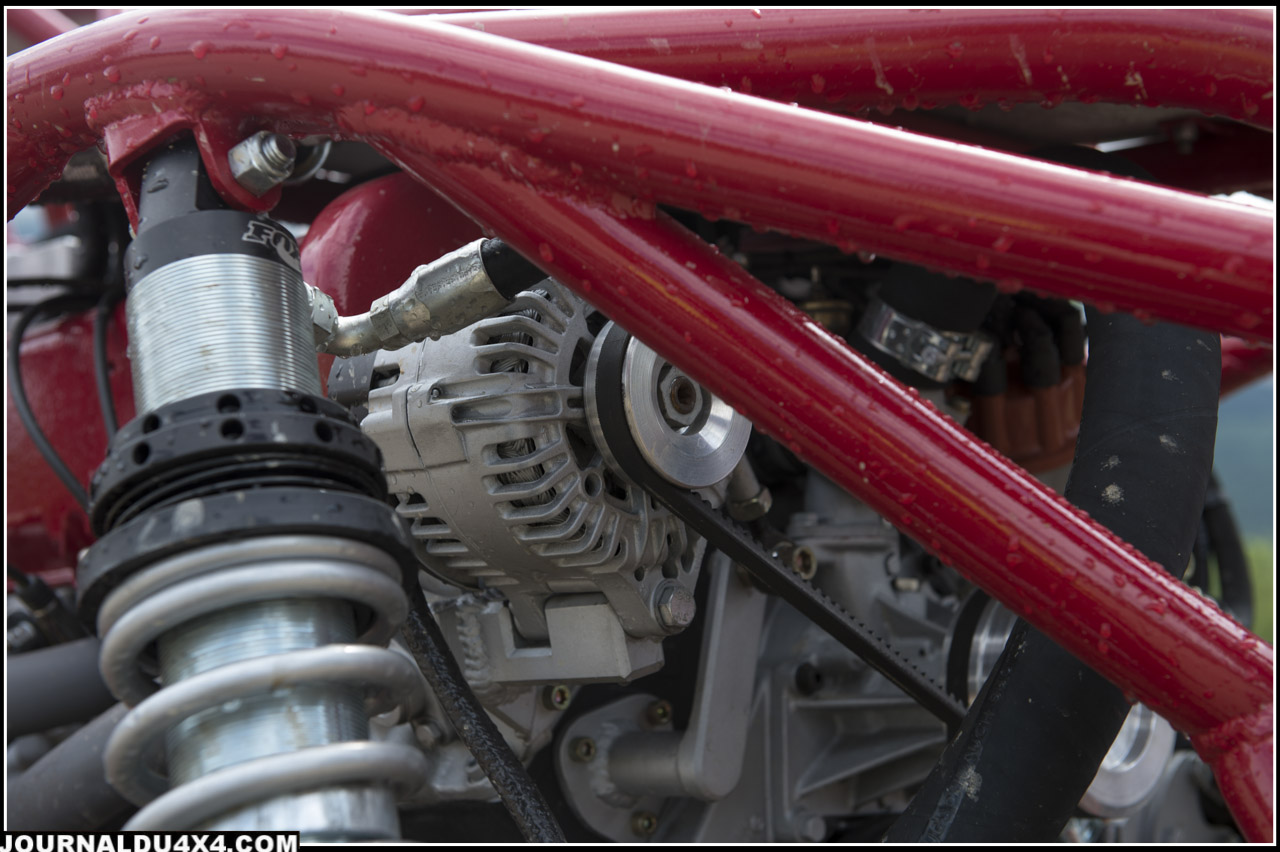

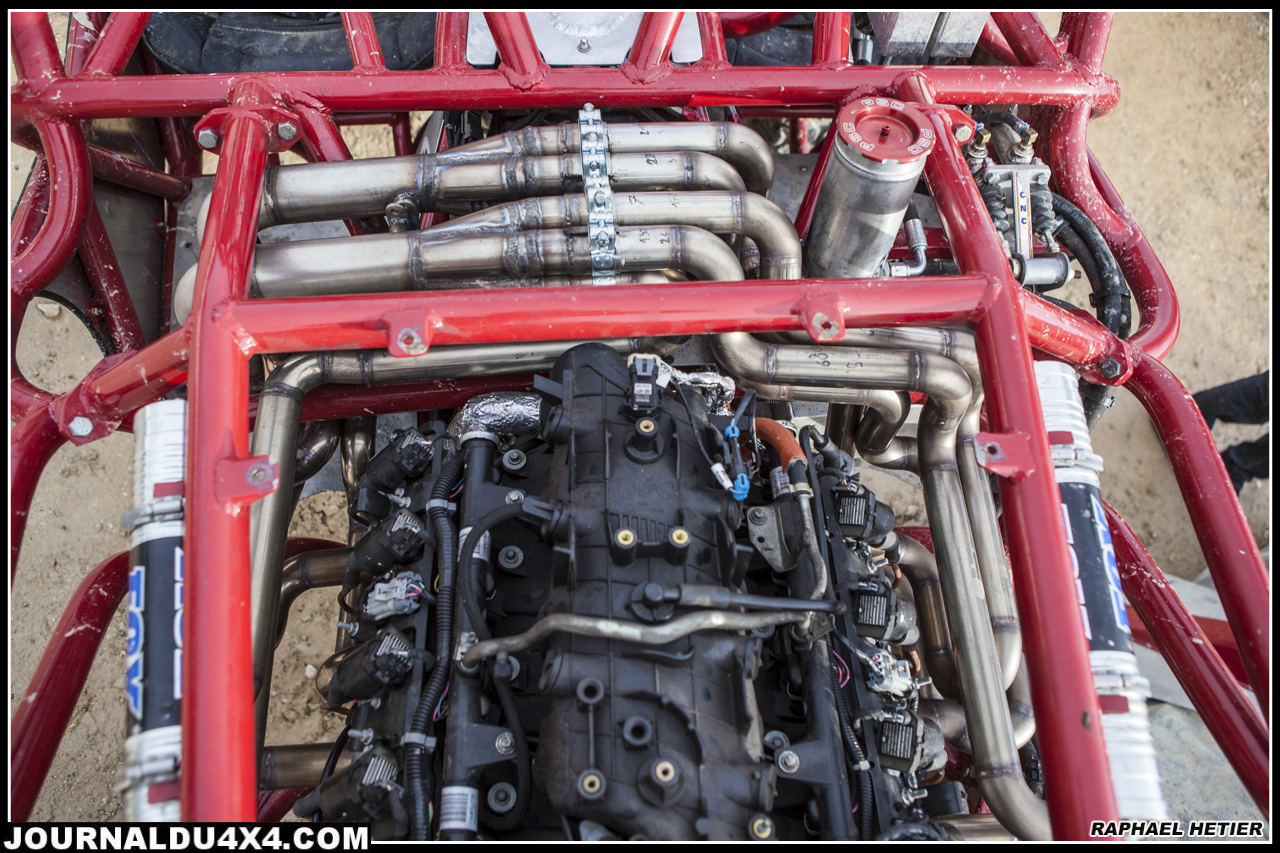

On the engine side, he stopped playing with Lada engines ; lets jump directly to the V8. A big 6.9L Mercedes V8 (300hp and 400lbs-ft) bought from Cédric Kalvas and coming from a ’74 Mercedes 450 SEL.

There was only 8200 units produced and this is the number 105. He spent 5 days on the engine because it didn’t run for several years, and then decide to put in Agrippa. Small tip : the coolant is routed directly through the chassis tubes !

One of the special features of this engine is its dry sump, the oil is located in a separated tank, which minimize loss of power and allows a complete lubrication in all positions. No more trouble if the buggy is on its lid or in scabrous situations.

For its transfer case, Fabrice trusted a fully upgraded Dana 300 and the gearbox is a TCI built TH350, obviously, he had to engineer a custom engine to gearbox adapter as nothing exists for this Mercedes engine. He also machined custom pullies and did the headers.

He’s working without any blueprints, but obviously everything is planned to go in an optimal way, suspension and link placement have been meticulously located, because they are the key elements that, associated with a good weight repartition, will give the buggy good handling characteristics.

Moreover, as each part (including seats and steering wheel) has been bought before the start, he didn’t have any fitments issues. Let’s go back to the weight repartition ; Fabrice weighted every component which enabled him to put them in a very precise way to obtain a pre-calculated ratio of 55% – 45% (front – rear).

Suspensions have been sponsored by par Euro4x4parts (being one Fabrice’sponsors since the Tas de Tube creation). He chose Fox 2.5”x14” Coilovers with Eibach coils. Bumpstops are hydraulic, Fox 2.0”x3”

Suspensions are two 4links. To stabilize the buggy, there is an Antirock Sway bar from Currie Enterprises. No suckdown winch but some limit straps instead.

Tires 42” PitBull Rocker are installed on steelies with custom GoldenCoasCustom designed laser cut center sections and beadlocks.

The two axles are fitted with Detroit Lockers and the use of front/rear cutting brakes in conjunction with 45 deg of steering allows to park Agrippa waaaay better than a twingo… Yes, I assure you !

Fuel tank is fitted with a dual pump system and a surge tank, allowing to feed the engine in any position which is important due to the planned use.

A big dual pass cooler and two SPAL fans are in change of the cooling.

OTHER DETAILS

In general in my articles I always do a comment like : “It’s nice and shinny, but does it works OffRoad ?”. This time, I just said to myself I was going to show you some of my photos…

LET’S ROCK !

You get the idea, right ?

EVOLUTIONS : AGRIPPA’S 2013 UPGRADE

As it’s not really possible to improve the old engine power, our friend decided to transplant the heart of Agrippa.

Between the build of Crixus (Crixus un bouncer qui allie performance et budget serré), a Monster Garage style operation (Monster Garage : une semaine pour créer le TasDeTube3) and some diverse things, Fab worked on Agrippa.

Here is the list of what he did :

change the Dana 300 with a 4.3 Atlas 2

change the Mercedes engine for a 5.3 Vortec from Pacific Fabrication. It’s fitted with a marine harness and reflashed ECU. Being an LS-style engine, performance mods will be much easier

rework the rear driveshaft

modify the rear squat/anti squat and lengthen the wheelbase by 2″

make a new dashboard

improve the cooling system

create two wicked TIGed stainless 180 deg headers

If you’re saying to yourself “WTF is that last thing ??” ; 180 deg headers are a very special set of headers. As GM V8s crankshafts are cross-plane units, by using a 180 deg headers you can match the exhaust pulses on a 90 degree V8, making the engine act (and sound) like a flat plane-crank V8. This allows a torque and power increase, as well as better revving. The sound is also very unique.

This system was used on Showtime and Green Goblin (Tim Cameron)

Let’s see these changes in pictures :

READY TO RIDE WITH FAB ?

AGRIPPA IN THE TRUCK HILLS

THEY ARE USED IN THE EUROPEAN TRIAL TRUCK IN MONTALIEU

AGRIPPA, FREERIDE IN MONTALIEU

JUMP !

A happy man :

And my personal favorite :

Here is the build sheet :

| Brand | GoldenCoastCustom |

| Year | 2012 |

| Builder | Fabrice RAVENET |

| Model | Agrippa |

| Length of build | 4 months |

| Châssis | GoldenCoastCustom |

| Cage material | DOM / Seamless Tube. 42mm OD 3.2mm Wall |

| Length | 3m96 = 12ft 12in |

| Width | 2m30 = 7ft 6.5in |

| Heigth | 1m88 = 6ft 2in |

| Wheelbase | 116” (version I) / 118” (version II) |

| Weight | 1800 kg = 3968 lbs |

| Engine (version I) | Mercedes |

| Displacement | 6.9L |

| Output | 300hp / 55mkg = 400 lbs-ft |

| Fuel injection | K-jetronic |

| Special features | Dry Sump |

| Comments | Comes from a ’73 450 SEL |

| Engine (version II) | GM Vortec LM7 |

| Displacement | 5.3L |

| Output / Torque | 300cv / 55mkg = 400 lbs-ft |

| Fuel injection | stock with marine harness and reflashed computer |

| Exhaust | custom 180 headers |

| Battery | Red Optima |

| Radiator / Fan | Aluminium / SPAL |

| Intake | GCC, custom made with K&N filter |

| Transmission | TCI TH350 |

| Torque converter | TCI |

| Cooling | Coolant through the tubes of chassis |

| Shifter | GoldenCoastCustom |

| Transfer Case (version I) | DANA300 + 32 splines input/output + 4 to 1 LoMax gears + Chromoly flanges |

| Transfer Case (version II) | Atlas2, 4.3 |

| Tanks | AluSport 30L + 5L surge tan + dual pumps |

| Skid plates | Steel, 5mm |

| Floor | Aluminum 2mm |

| Gages – Switches | RPM, water temp, oil pressure, voltage |

| Steering | Full-Hydraulic steering by PSC : SE Ram, Column + Quick disco + Steering wheel by PSC |

| Pedals | Brakes : CNC single pedal with dual MC / Accelerator : Custom Made, with rods and joints, no cable. |

| Harnesses / seats | 4 points 3” belts cam lock / Jazz seats with custom upholstering |

| Front Suspension / type / material | W 4 link with Currie JJ and 20MV6 link |

| Front Bump stops | 3”Fox Nitrogen |

| Front Diff / Locker | Dana 60 / Detroit Locker |

| Cover | SolidAxle |

| Axleshafts + CV joint | RCV |

| Front Brakes | Dana44 |

| Front driveshaft | Mercedes based custom unit with custom pillow block |

| Rear Suspension / type / material | W 4 link with Currie JJ and 20MV6 link |

| Rear Bump stops | 3”Fox Nitrogen |

| Rear Diff / Locker | 14 bolts / Detroit Locker |

| Cover | SolidAxle |

| Axleshafts + Drive flange | RCV |

| Rear Brakes | Dana44 |

| Rear driveshaft | Mercedes based custom unit |

| Tires | PitBull Rocker 42” |

| Wheels | Steel with custom center and beadlocks. Design, programming and cutting by GCC |

Most of the parts come from a young French import company :

http://www.4krawl-products.com

Translation by Bebop